Borehole heat exchanger designs

Introduction

Heat pump-based installations competing with other methods of supplying heat to buildings must be efficient, simple to operate and inexpensive. For this reason, borehole-based installations, or borehole heat exchangers, have become increasingly popular. These exchange heat with the ground, eliminating the need for the heat carrier to come into contact with the groundwater. The use of borehole heat exchanger installations alone does not require water permits or a mine plan (Złotkowski, 2009).

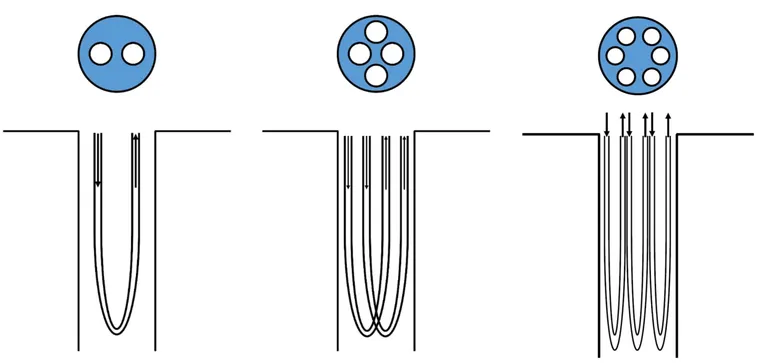

Borehole heat exchanger designs

The design of a borehole heat exchanger has an important influence on the effectiveness of its subsequent use. Optimal heat transfer occurs when the individual baffles have the lowest possible thermal resistance and convection occurs where possible. There are several ways to increase the efficiency of borehole heat exchangers (Śliwa et al., 2016):

- using a sealing slurry with the highest possible thermal conductivity value,

- filling the borehole with sealing slurry up to the surface,

- using pipes made of material with the highest possible thermal conductivity,

- using ducts with the smallest possible wall thickness that provides adequate strength,

- using pipes that increase the turbulence of the heat carrier flow, use of spacers that keep the ducting as close to the borehole wall as possible,

- the use of a heat carrier with as low a dynamic viscosity as possible,

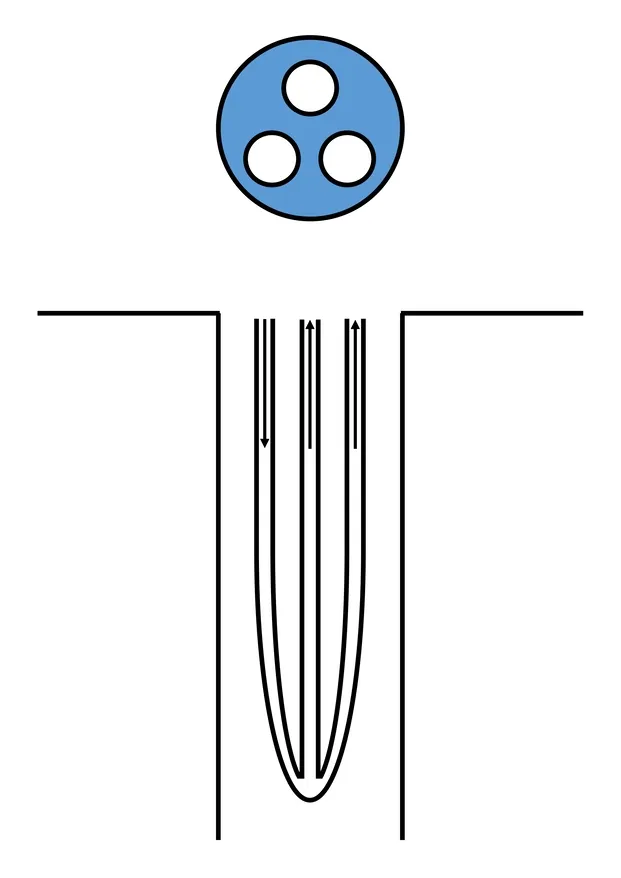

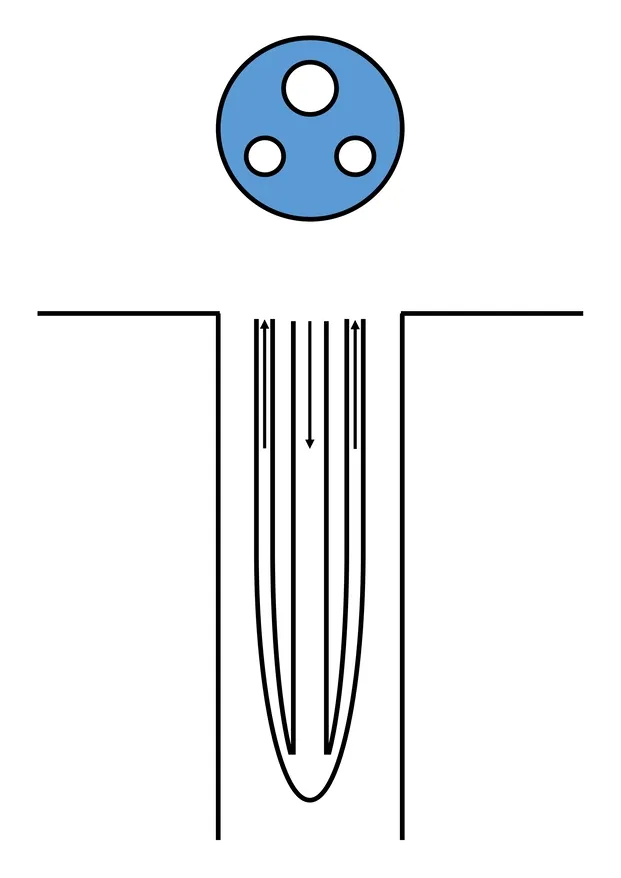

- the use of double U-tubes, triple U-tubes or a combined pipe system.

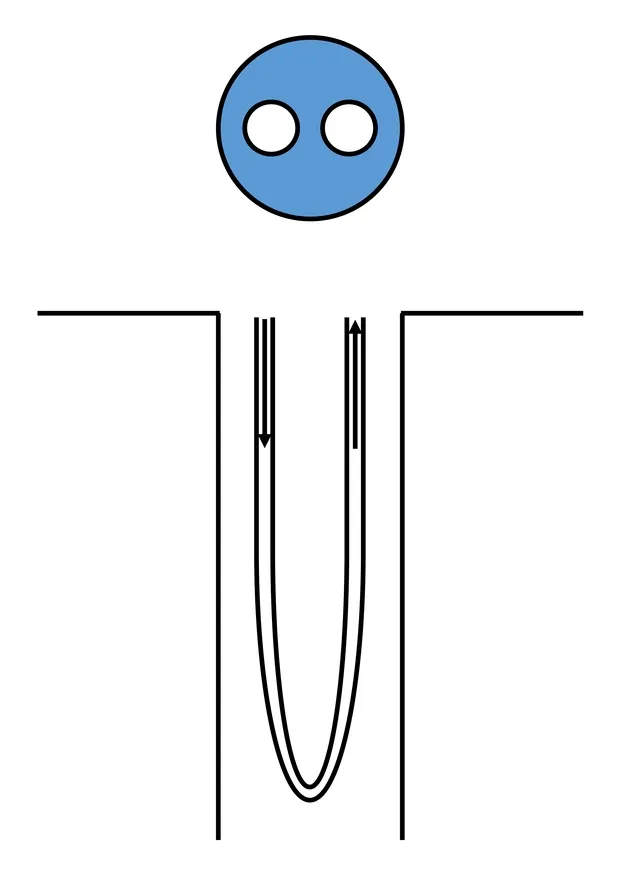

Single U-tube

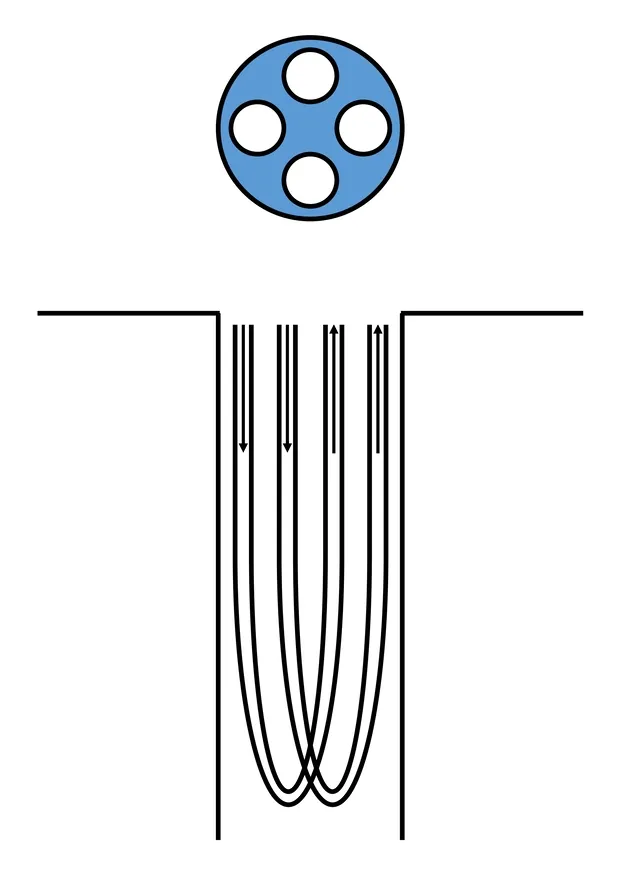

Double U-tube

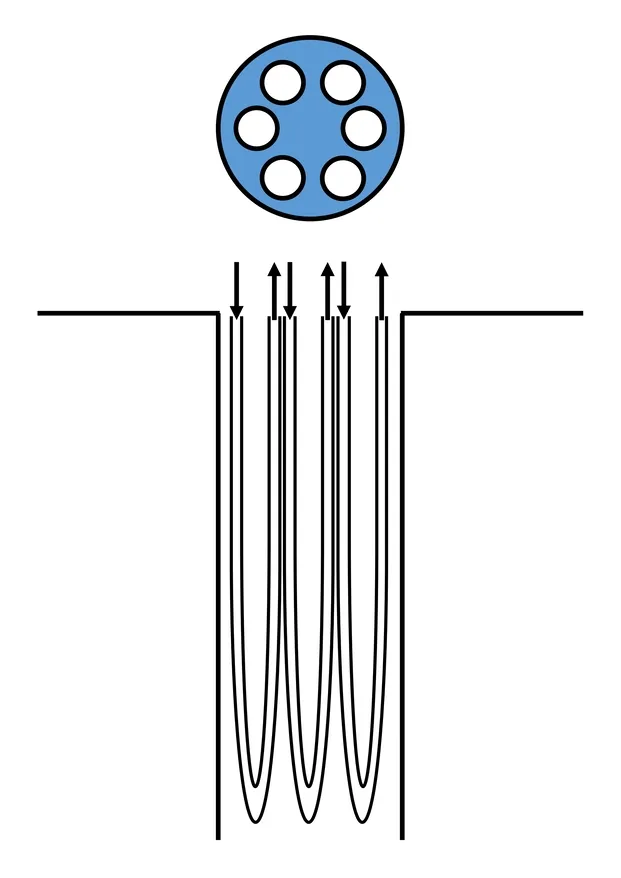

Triple U-tube

3-tube system (3 identical diameters)

3-tube system (two smaller diameters, one larger)

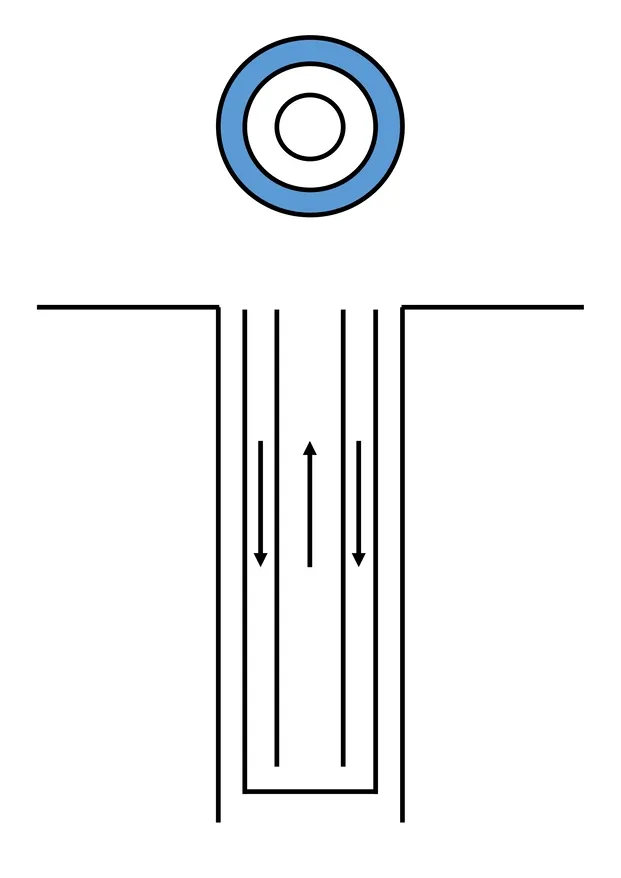

Co-axial system

Summary

Various types of borehole heat exchangers are available on the Polish market, which are characterised by differences:

- the shape of the hydraulic pipes,

- the diameter and wall thickness of the hydraulic pipes,

- the number of hydraulic pipes,

- structure of the internal surface of the pipes,

- sealing technology of the borehole heat exchanger.

The most commonly used tubes for the construction of borehole heat exchangers are the commonly available circular tubes. Tubes used in borehole heat exchangers range in diameter from 25 to 90 mm (in the case of a co-axial design). Usually all pipes used in the exchanger have the same diameter. To improve the efficiency of the exchangers, pipes of different diameters and wall thicknesses can be used, along the entire length or only in part. This will reduce heat transfer between the pipes and reduce the time for the heat transfer medium to flow from the bottom of the exchanger to the surface (Zlotkowski, 2019).

A borehole heat exchanger, made in the traditional way, is equipped with tubes that are unwound from a spool to a length corresponding to the depth of the borehole. However, there is an alternative to this method, which involves inserting the casing tubes by butt-welding successive tube segments (so-called pieces). This method of creating borehole heat exchangers is characteristic of a centric heat exchanger, where the outer and inner pipe, or just the outer pipe, are joined on site. However, due to the difficulty and labour-intensive nature of this process, centric borehole heat exchangers are currently not as common as the single U-tube (Śliwa and Gonet, 2011).

Literature

- Śliwa, T. i Gonet, A., 2011. Otworowe wymienniki ciepła jako źródła ciepła lub chłodu na przykładzie Geoenergetics Laboratory WWNiG AGH (Borehole heat exchangers heat or cool source on the basis of Laboratory of Geothermics of Drilling, Oil and Gas Faculty in AGH University of Krakow). Wiertnictwo, Nafta, Gaz, 28(1-2), pp. 419-430.

- Śliwa, T. i inni, 2016. Borehole heat exchangers: production and storage of heat in the rock mass. Kraków: Drilling, Oil ans Gas Foundation.

- Złotkowski, A., 2009. Wybrane aspekty podziemnego magazynowania ciepła. Praca magisterska. Kraków: Wydział Wiertnictwa, Nafty i Gazu Akademia Górniczo-Hutnicza w Krakowie.

- Złotkowski, A., 2019. Opracowanie wieloetapowego testu reakcji termicznej otworowych wymienników ciepła. Kraków: Doctoral thesis - AGH.