Thermal Response Test - (TRT) - a way to correctly design a borehole heat exchanger installation

Introduction

For a correct design of a borehole heat exchanger system with a ground source heat pump, it is important to know the following information:

- energy yield of a borehole heat exchanger ,

- thermal conductivity of the drilled rock profile ,

- borehole thermal resistance ,

- average rock mass temperature .

The study that allows the determination of the above-mentioned information is the Thermal Response Test (TRT).

History of the TRT

The first thermal response test was carried out in Sweden (Mogensen, 1983). Mogensen presented the concept of the test and its application to measurements to estimate the thermal conductivity of a rock mass drilled through a borehole heat exchanger. In 1995, work began on experimental equipment at Oklahoma State University, which was described by Austin in 1998 (Austin, 1998). During the same period, research was conducted independently in Sweden.

The first test performed was described by Eklof in 1996 (Eklof and Gehlin, 1996). (Gehlin and Nordell, 1998) in 1998 presented the results of the TRT interpretation. In order to properly design borehole heat exchangers, a TRT must be carried out on site, in the first (test) borehole, using mobile test equipment.

The first thermal borehole test that was similar to a TRT, performed in Poland and reported in the literature, was presented by Czekalski in 2006 (Czekalski and Obstawski, 2006). The first commercial (industrial) TRT in Poland was performed in 2007, as described by Śliwa in 2011 (Śliwa and Gonet, 2011).

Thermal Response Test

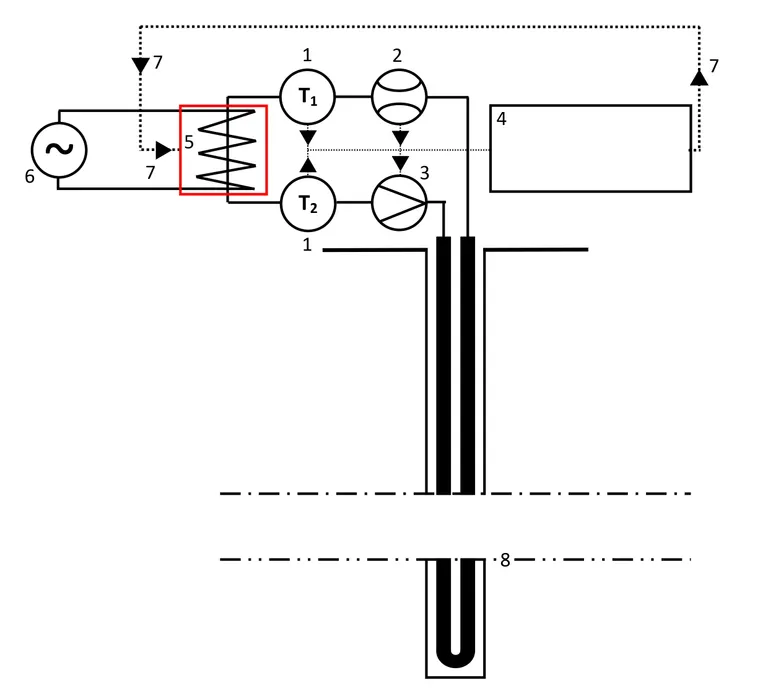

The measurement system for the realization of TRT must, on the one hand, take into account the model measurement scheme and, on the other hand, be adapted to the specific characteristics and conditions of borehole heat exchangers. The structure of borehole heat exchangers allows the transfer of energy through the heated heat carrier, which circulates in a closed circuit, corresponding to a linear heat source surrounded by rock.

During the measurement, the temperature values of the heat carrier flowing into and out of the borehole heat exchanger are measured and recorded. In addition, the volume flow rate of the flowing heat carrier and the delivered heating power are monitored throughout the measurement. These two parameters should maintain a constant value throughout the TRT (Śliwa, 2012).

A sufficiently long test period is a prerequisite for obtaining correct results and enabling correct interpretation. This time should allow for temperature changes not only within the material filling the borehole, but also in the surrounding rock mass. The duration of the TRT depends on the geological conditions, the minimum time being determined as 70 hours (Złotkowski, 2019).

When measuring in a surface system, it is important to minimize the influence of atmospheric conditions on the survey cycle being carried out. A good solution is to wrap the connection pipes with thermal insulation between the TRT unit and the borehole heat exchanger (Śliwa and Gonet, 2011).

Determination of the average temperature of a borehole heat exchanger

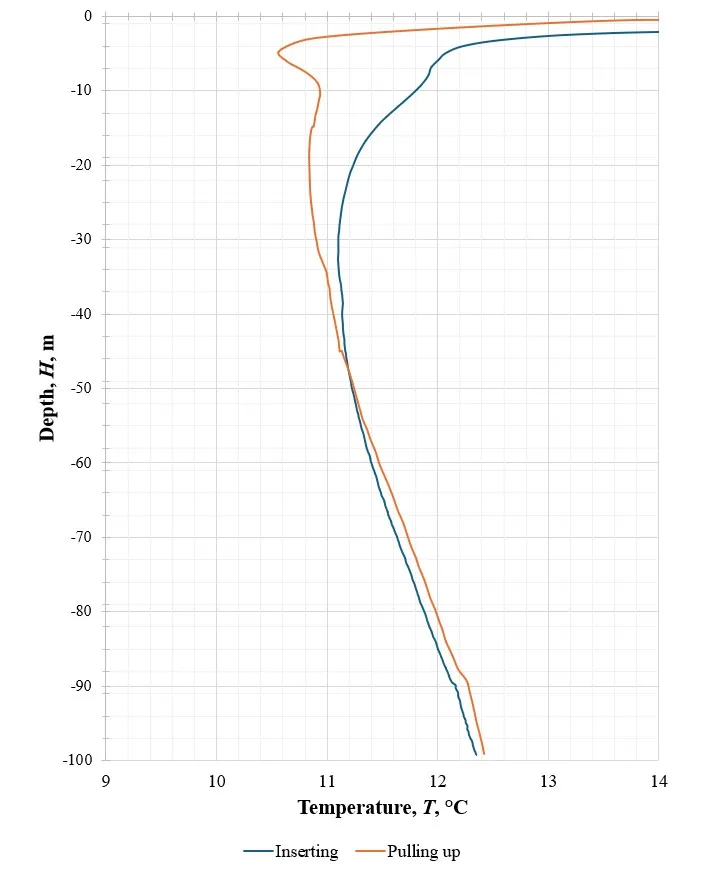

For subsequent interpretation of the TRT results, information on the average borehole temperature is needed. GeoTec Energy Sp. z o.o. performs temperature profiling using two methods to accurately determine the temperature.

Method I (logger NIMO-T)

The method involves inserting a logger into the borehole heat exchanger, which reads the temperature and pressure values during free fall to the bottom of the borehole heat exchanger. After reading the data, the average temperature over the entire depth of the borehole heat exchanger is calculated.

Method II (circulation of the heat carrier)

Prior to the start of the heating phase, a heat carrier circulation is carried out between the borehole exchanger and the TRT unit to determine the average temperature. The duration of the circulation is 24 h.

Interpretation of results

After the TRT is carried out, interpretation of the results is performed. GeoTec Energy performs it using three methods:

- classic method (I),

- point method (II),

- constant resistance method (III).

A table with the data obtained after the interpretation of the TRT results is shown below (example data).

| Value name | Value |

|---|---|

| Depth of borehole heat exchanger | = 100 m |

| Effective thermal conductivity in the borehole heat exchanger | = 1,94 |

| Borehole heat exchanger unit power | = 37,58 |

| Borehole thermal resistance | = 0,088 |

| Average natural temperature in the borehole heat exchanger | = 10,54C |

References

- Austin, W., 1998. Development of an In-Situ System for Measuring Ground Thermal Properties. Oklahoma: Oklahoma State University.

- Czekalski, D. i Obstawski, P., 2006. Procedura testowania pionowego wymiennika gruntowego w warunkach eksploatacyjnych. Ciepłownictwo, Ogrzewnictwo, Wentylacja, Issue 4, pp. 18-21.

- Eklof, C. i Gehlin, S., 1996. A mobile Equipment for Thermal Response Test. Lulea: Lulea University of Technology, Sweden.

- Gehlin, S. i Nordell, B., 1998. Thermal Response Test of Boreholes - Results from In Situ Measurements.

- Mogensen, P., 1983. Fluid to Duct Wall Heat Transfer in Duct System Heat Storages., Swedish Council for Building Research.

- Śliwa, T. i Gonet, A., 2011. Otworowe wymienniki ciepła jako źródła ciepła lub chłodu na przykładzie Geoenergetics Laboratory WWNiG AGH (Borehole heat exchangers heat or cool source on the basis of Laboratory of Geothermics of Drilling, Oil and Gas Faculty in AGH University of Krakow). Wiertnictwo, Nafta, Gaz, 28(1-2), pp. 419-430.

- Śliwa, T., 2012. Badania podziemnego magazynowania ciepła za pomocą kolektorów słonecznych i wymienników otworowych. Kraków

- Złotkowski, A., 2019. Opracowanie wieloetapowego testu reakcji termicznej otworowych wymienników ciepła. Kraków: Doctoral thesis - AGH.